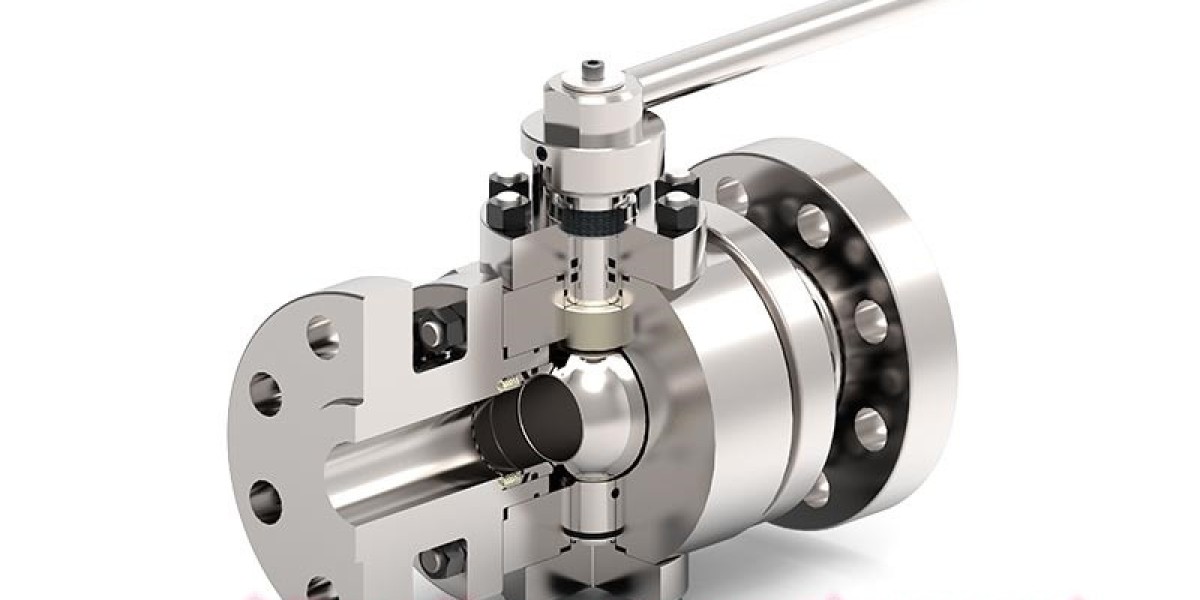

Precise control is a crucial requirement in modern fluid systems, and Metal Seated Ball Valves provide the mechanical accuracy needed to regulate flow reliably. At ncevalve, these valves are engineered to integrate seamlessly with automated systems, ensuring consistent response under varying operating conditions. Their robust construction allows for stable operation without compromising sealing or performance.

Automation compatibility requires careful consideration of torque, stem alignment, and actuator interfaces. Optimized design minimizes variability in movement while maintaining predictable sealing under pressure. Engineers focus on reducing hysteresis and friction within the valve mechanism, which helps achieve smooth, repeatable adjustments when integrated into control networks. This ensures the valve responds precisely to automated signals, maintaining process stability.

Long-term performance also depends on material durability and assembly precision. Advanced alloys and heat-treated surfaces resist wear and erosion, while careful machining preserves tight tolerances. These measures reduce maintenance frequency and ensure that the valves sustain operational integrity across years of cyclic use. Surface treatments protect against corrosion, enabling reliable operation in challenging environments.

Maintenance strategies are centered on periodic inspections and preventive measures. Checking stem alignment, seat condition, and lubrication points helps avoid unexpected failures. When wear or minor damage is detected early, timely replacement or adjustment preserves the valve's performance without requiring extensive downtime. The combination of design foresight and proactive maintenance contributes to operational reliability.

Valve integration within automated systems also benefits from intelligent monitoring. Sensors and diagnostic tools can provide real-time feedback on torque, flow rate, and pressure fluctuations. This data allows operators to fine-tune system settings, detect early signs of wear, and plan maintenance without interrupting production. The resulting combination of control precision and predictive maintenance extends the operational lifespan of the equipment.

Industries such as chemical processing, energy production, and specialized manufacturing benefit from this approach. Reliable automated control reduces manual intervention, while robust construction and proactive monitoring improve system safety and reduce operational risks. The result is a valve solution that maintains consistent flow, resists mechanical stress, and provides predictable performance over long periods.

In conclusion, Metal Seated Ball Valves from ncevalve combine precise automation compatibility with strategic maintenance design to maximize control and lifespan. Their durable materials, optimized geometry, and predictable operation ensure reliable performance in demanding industrial applications. Detailed product specifications are available at https://www.ncevalve.com/product/special-condition-ball-valve-1/metal-seat-ball-valve.html