As electronic devices become smaller, faster, and more powerful, the microchips and circuit assemblies that enable their performance become significantly more vulnerable to environmental hazards, including electrostatic discharge. Even minor exposure to static can cause irreversible, latent, or intermittent failures. Such failures are notoriously difficult to diagnose later in the product lifecycle, making static protection critical during the earliest phases of assembly, shipping, and handling. This shifting landscape has raised the strategic importance of anti static packaging in both high-volume consumer electronics and mission-critical industrial electronics applications.

The Anti Static Bags For Electronic Market is influenced not only by material science advancements but also by geographic manufacturing trends. Analysts use approaches similar to those used when evaluating Glass Ionomer regional insights to understand how adoption varies across markets. For instance, Asia-Pacific represents the largest concentration of semiconductor and PCB assembly operations, resulting in sustained regional demand for static-safe packaging. North America and Europe, meanwhile, demonstrate increased demand in areas such as aerospace and medical-grade electronics where product reliability requirements are exceptionally strict.

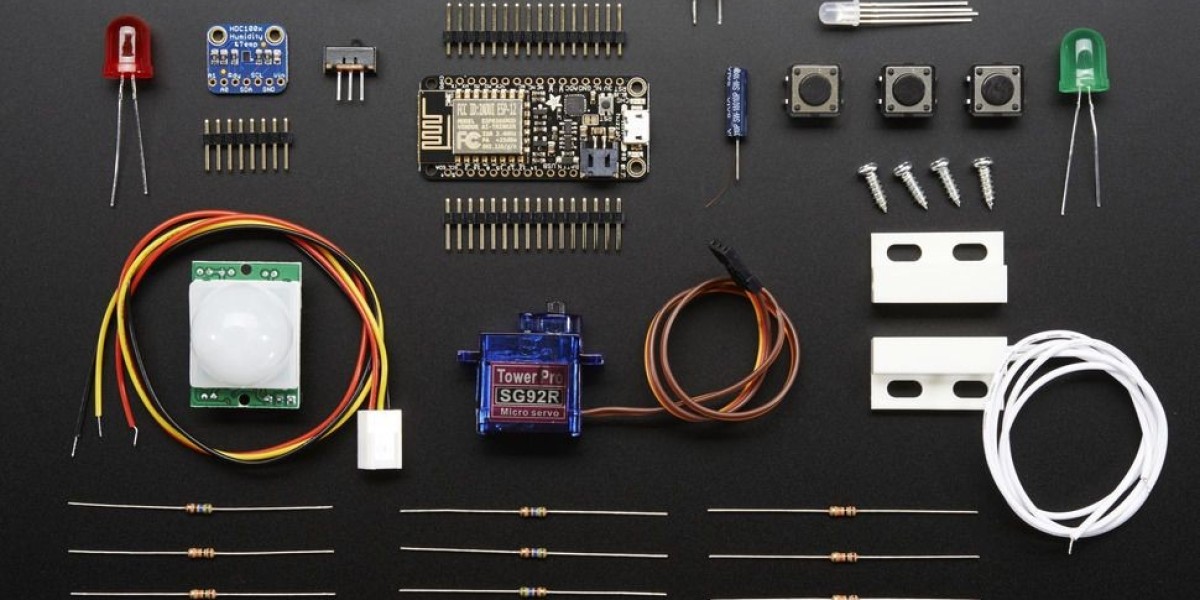

The market is highly segmented by application type. Static shielding bags remain the dominant choice for safeguarding advanced microprocessors, memory chips, optical sensors, and precision PCBs. Pink anti static bags are frequently used for supporting components, accessories, and lower-risk handling environments. Black conductive bags are appropriate for controlled facility conditions where grounding and environmental charge neutralization are strictly managed.

Technological innovation in materials continues to drive the market forward. Modern anti static packaging incorporates low-resistivity polymers, moisture-resistant coatings, and multi-layer conductive shielding films. These enhancements allow packaging to remain stable, even under fluctuating temperatures and humidity levels frequently encountered during shipping across long supply chains. Additionally, certain manufacturers have begun integrating traceability technologies into anti static packaging, including serialization and embedded handling data.

Sustainability considerations continue to gain importance as environmental regulations tighten. For producers with global manufacturing operations, packaging waste reduction has become an essential strategic objective. In response, some companies are investing in reusable static shielding containers and recyclable film formulations. Although recyclable anti static material development remains technically challenging due to conductive additives, ongoing R&D suggests promising advancements.

The future of the market is expected to align closely with semiconductor process development, global supply chain capabilities, and advances in material science. As industries demand higher reliability at smaller component sizes, the need for precise static-safe packaging solutions will continue to expand across regions.