In industries where accuracy and efficiency are critical, even the smallest error in machine movement can cause major issues. Low-quality bearings often lead to vibration, misalignment, and early failure. These problems not only slow production but also increase costs through constant maintenance.

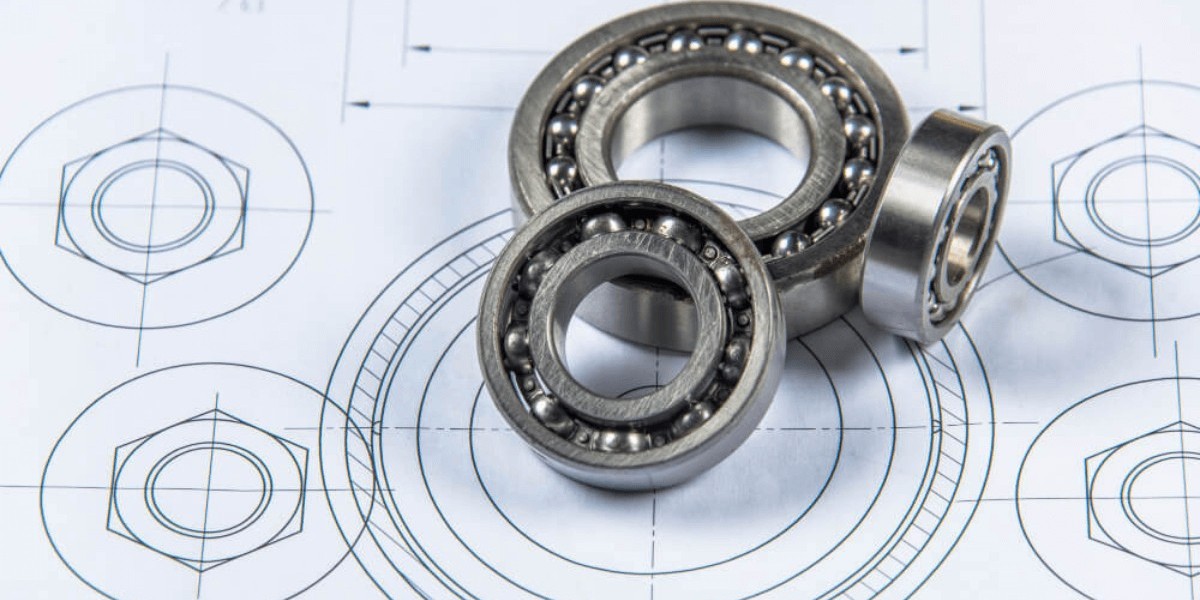

The answer lies in using a precision bearing. Built with advanced design and strict tolerances, precision bearings are engineered to handle demanding applications with stability and accuracy.

Why Ordinary Bearings Cause Problems

While standard bearings work for general machinery, they often fail under high-speed or high-load conditions. Common issues include:

Frequent breakdowns due to poor material strength.

Excessive noise and vibration reducing machine accuracy.

Overheating from friction and misalignment.

Short service life, requiring frequent replacements.

These limitations make ordinary bearings unsuitable for industries that rely on consistent precision.

Key Advantages of Precision Bearing

A high-quality precision bearing offers several advantages that help eliminate downtime and improve performance:

Superior Accuracy – Designed with tighter tolerances for stable performance.

Durability – Made from high-grade steel and advanced materials.

High-Speed Capability – Ideal for machines that operate under rapid movement.

Reduced Friction – Smooth rotation minimizes heat and energy loss.

Extended Service Life – Long-lasting operation reduces replacement costs.

These benefits ensure long-term reliability and efficiency in critical operations.

Industries That Rely on Precision Bearings

Precision bearings are widely used across industries where accuracy is essential:

Automotive – gearboxes, transmissions, and engines.

Aerospace – turbines, navigation systems, and control units.

Robotics – ensuring stable, accurate movement.

Medical Equipment – scanners, surgical devices, and diagnostic machines.

Manufacturing & Energy – high-speed machinery and turbines.

By using precision bearings, these industries achieve smoother operation, fewer breakdowns, and improved productivity.

How to Select the Right Precision Bearing

When choosing a supplier, companies should look for:

Experience – proven track record in global industries.

Quality Control – strict testing and international certifications.

Range of Products – availability of different types and sizes.

Technical Support – expert guidance for installation and maintenance.

Selecting the right partner ensures long-term value and machine reliability.

Conclusion

Low-quality bearings may seem cost-effective, but they create more problems in the long run. For businesses where performance and accuracy are essential, choosing the right precision bearing is the smartest investment.

By reducing downtime, extending machine life, and improving operational accuracy, precision bearings deliver long-term value for industries worldwide.