Prefabricated Steel Building Systems Market Overview

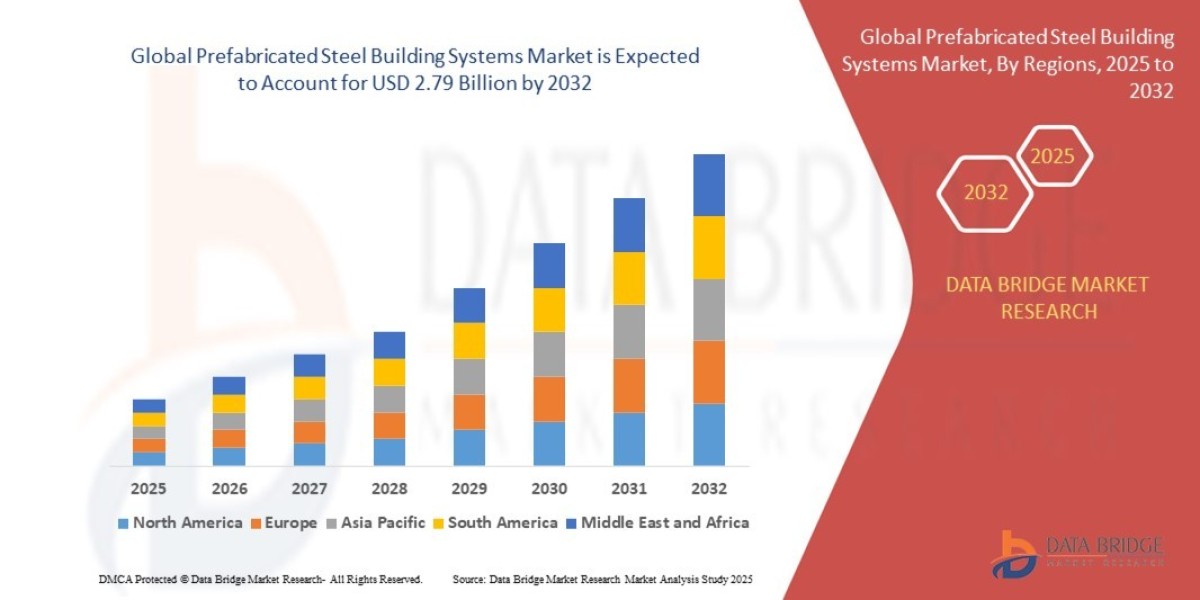

The Prefabricated Steel Building Systems Market Size is experiencing robust growth, driven by increasing construction activities, growing demand for sustainable building materials, and the rapid adoption of modular construction techniques. The market was valued at approximately USD 2.01 billion in 2024 and is expected to reach USD 2.79 billion by 2032, growing at a CAGR of 4.20% during the forecast period.

Prefabricated steel buildings, known for their durability, cost-effectiveness, and quick assembly, are becoming a preferred choice in industrial, commercial, and residential construction. These systems use pre-engineered steel components that are manufactured off-site and assembled on-site, minimizing construction time and waste.

The surge in infrastructure development, urbanization, and green construction initiatives is fueling demand for these systems across the globe. Additionally, the versatility of steel structures—allowing for customization and expansion—makes them highly suitable for warehouses, factories, offices, and public buildings.

Competitive Landscape

The Prefabricated Steel Building Systems Market is moderately consolidated, with global and regional players competing on technology, design, and cost efficiency. Major participants focus on product innovation, strategic partnerships, and capacity expansion to strengthen their market presence. Major market participants include

Prefabricated Steel Building Systems Market Drivers

- Rapid Urbanization and Industrial Expansion

The growth of industrial and commercial sectors is one of the strongest drivers of the prefabricated steel building systems market. The rise in manufacturing, logistics, and e-commerce facilities demands large, durable, and cost-efficient structures that can be quickly built, making prefabricated steel systems the ideal choice. - Growing Adoption of Sustainable Construction Practices

With a global shift toward environmentally friendly construction, steel buildings—being recyclable and energy-efficient—are gaining traction. Steel components can be reused and reassembled, reducing material waste and lowering the carbon footprint of projects. - Reduced Construction Time and Cost

Prefabrication allows faster project completion as components are produced simultaneously with site preparation. This significantly cuts down labor costs, material waste, and overall project duration—benefiting developers and contractors. - Technological Advancements in Steel Fabrication

Modern technologies such as computer-aided design (CAD), building information modeling (BIM), and automated steel fabrication have enhanced precision, design flexibility, and productivity in prefabricated construction. - Growing Popularity in Residential Construction

Although traditionally associated with industrial and commercial buildings, prefabricated steel structures are increasingly being used in residential projects for eco-friendly housing, modular homes, and emergency shelters.

Prefabricated Steel Building Systems Market Trends

- Integration of BIM and 3D Modeling: Enhances accuracy and enables efficient project planning.

- Rise of Modular Construction: Prefabrication is central to the modular building trend, providing scalable, relocatable solutions.

- Use of High-Strength, Lightweight Alloys: Improving performance and load-bearing capacity while reducing overall structure weight.

- Expansion of Smart and Green Buildings: Energy-efficient steel designs incorporating solar panels, insulation materials, and smart systems.

- Customization and Aesthetic Design Improvements: Growing use of architectural steel in visually appealing structures such as malls, stadiums, and high-end offices.

Prefabricated Steel Building Systems Market Segmentation

By Type:

- Pre-Engineered Buildings (PEB)

- Modular Steel Buildings

- Light Gauge Steel Frame Buildings

- Others (Hybrid Structures)

By End-Use Industry:

- Industrial (Factories, Warehouses, Power Plants)

- Commercial (Offices, Retail Centers, Stadiums)

- Residential (Apartments, Modular Homes)

- Institutional (Schools, Hospitals, Airports)

By Construction Type:

- New Construction

- Reconstruction and Expansion

By Application:

- Permanent Buildings

- Temporary or Portable Structures

Regional Insights for Prefabricated Steel Building Systems Market

North America:

Holds a substantial Modular construction solutions market share, driven by the growing adoption of advanced construction technologies and the increasing trend of warehouse automation. The U.S. leads the region with rising investments in logistics centers, retail outlets, and energy infrastructure.

Europe:

Experiencing strong growth due to strict sustainability regulations and rising adoption of prefabricated, eco-friendly building systems. Countries like Germany, the U.K., and France are leading in steel structure integration in both public and private sectors.

Asia-Pacific:

Expected to dominate the global market throughout the forecast period, fueled by rapid urbanization, population growth, and government-led infrastructure development projects. China, India, Japan, and South Korea are key contributors to regional expansion.

Latin America:

Witnessing steady growth with increased investments in industrial and commercial facilities, particularly in Brazil and Mexico.

Middle East & Africa:

Poised for expansion due to mega infrastructure projects, tourism-related developments, and increased adoption of steel systems in commercial complexes and airports.

Emerging Opportunities in Prefabricated Steel Building Systems Market

- Development of eco-friendly coatings and corrosion-resistant materials to extend the life of steel structures.

- Integration of IoT-enabled monitoring systems for smart construction management.

- Rising demand for prefabricated healthcare facilities and data centers.

- Increased use of lightweight, high-tensile steel alloys for high-rise construction.

- Growth of modular housing projects in emerging economies addressing affordable housing shortages.

Prefabricated Steel Building Systems Market Future Outlook

The Prefabricated Steel Building Systems Market Outlook is set to continue expanding rapidly as global construction priorities shift toward speed, sustainability, and cost efficiency. With advanced technologies like BIM, automation, and smart fabrication shaping the industry, prefabricated steel structures are poised to redefine modern construction practices.

By 2032, the market is expected to exceed USD 2.79 billion, with Asia-Pacific at the forefront of adoption, followed by North America and Europe. As governments and industries seek faster, greener, and smarter construction methods, prefabricated steel systems will remain a cornerstone of global infrastructure growth.

Prefabricated Steel Building Systems Market Challenges

- High Initial Setup Costs: Advanced fabrication equipment and design tools require significant capital investment.

- Transportation Limitations: Large steel components can face logistical challenges in remote areas.

- Skilled Labor Shortages: Need for trained professionals familiar with prefabrication and steel assembly.

- Volatility in Raw Material Prices: Fluctuating steel prices can impact project costs and profitability.

- Perception Barriers: In some regions, traditional construction still dominates due to lack of awareness of prefabrication benefits.

For More Reports

Polyvinyl Chloride (PVC) Market

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact :

Data Bridge Market Research Private Ltd .

3665 Kingsway — Suite 300 Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)