Spunbond Market Overview

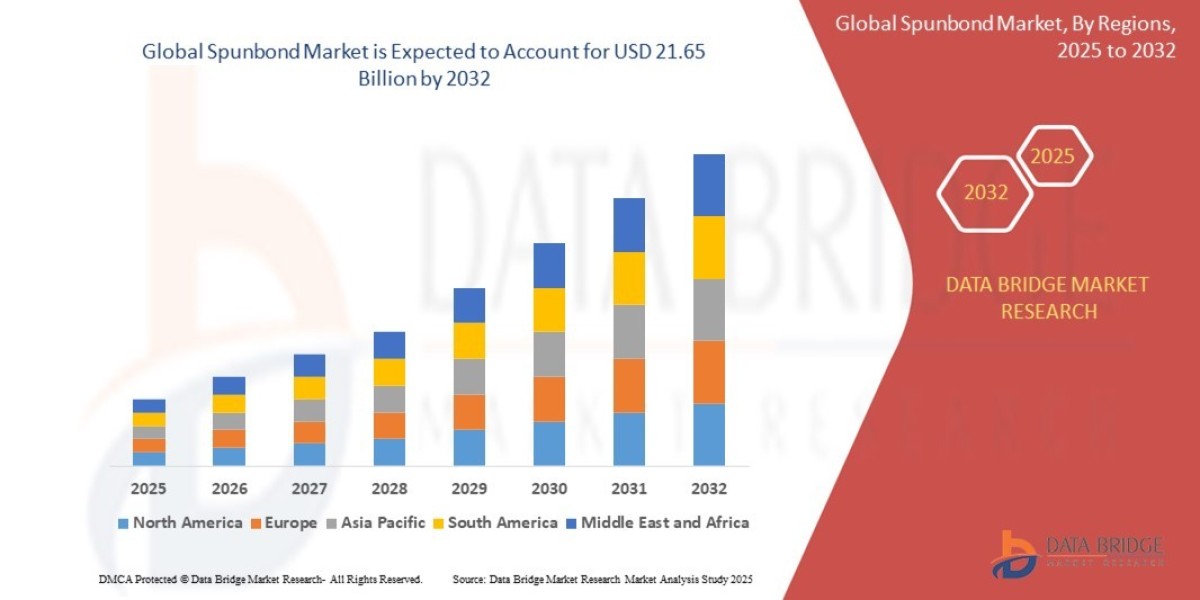

The Spunbond Market Size is witnessing strong expansion, driven by increasing demand for nonwoven fabrics across healthcare, hygiene, agriculture, and construction industries. The global spunbond market was valued at approximately USD 13.18 billion in 2024 and is projected to reach USD 21.65 billion by 2032, growing at a CAGR of 6.40% during the forecast period.

Spunbond fabrics are nonwoven materials produced through a spunbonding process, where thermoplastic polymers such as polypropylene (PP), polyester (PET), and polyethylene (PE) are extruded into continuous filaments, laid into a web, and bonded thermally. These fabrics offer advantages like high strength, durability, breathability, and cost-effectiveness, making them highly preferred in disposable hygiene products, medical applications, packaging, and agriculture.

The spunbond process involves extrusion of polymer granules into continuous filaments, which are then spread and bonded together to form nonwoven sheets. This process ensures uniform fiber distribution and high mechanical strength, making it suitable for both lightweight and heavy-duty applications.

Spunbond Market Competitive Landscape

The Spunbond Market is moderately consolidated with major players focusing on innovation, production capacity expansion, and sustainable manufacturing. Major market participants include Huahao Nonwovens Co., Ltd. (China), DuPont (U.S.), Asahi Kasei Corporation (Japan), Mogul Co., Ltd. (Turkey), Yaolong Spun bonded Nonwoven Technology Co., Ltd. (China) , Quanzhou Golden Nonwoven Co., Ltd. (China), TORAY INDUSTRIES, INC. (Japan), Berry Global Inc. (U.S.), Cerex Advanced Fabrics, Inc. (U.S.), Radici Partecipazioni SpA (Italy), Kolon Industries, Inc. (South Korea), APEX Nonwovens (U.S.), SHINKONG SYNTHETIC FIBERS CORP (Taiwan), Wenzhou Superteng Nonwoven Technology Co., Ltd. (China), Hadtex (Turkey)

Spunbond Market Drivers

- Growing Hygiene and Medical Sector

The surge in demand for disposable hygiene products such as diapers, sanitary napkins, and adult incontinence products is a major market driver. In healthcare, spunbond fabrics are used in surgical gowns, drapes, masks, and wound dressings, offering protection and comfort. - Expansion in Agriculture Applications

Spunbond nonwovens are widely used in crop covers, weed control fabrics, and greenhouse shading due to their lightweight, air permeability, and UV resistance. Rising focus on high-yield farming and climate-resilient agriculture further supports market growth. - Sustainability and Recyclability Trends

Manufacturers are shifting toward eco-friendly spunbond fabrics made from biodegradable or recycled polymers, reducing environmental impact and aligning with circular economy initiatives. - Increasing Demand for Lightweight and Durable Materials

Industries such as automotive, packaging, and filtration are adopting spunbond fabrics due to their lightweight structure, high tensile strength, and filtration efficiency.

Spunbond Market Trends

- Shift Toward Bio-Based Polymers: Use of polylactic acid (PLA) and other biodegradable polymers is rising in spunbond production.

- Technological Advancements: Integration of meltblown and spunbond processes (SMS, SMMS, SSMMS) to create multilayered fabrics with superior properties.

- Automation and AI in Manufacturing: Smart production lines ensure precision, quality consistency, and lower energy consumption.

- Increasing Demand for Medical Textiles: The post-pandemic healthcare expansion continues to drive medical-grade spunbond fabric production.

- Focus on Recycling and Waste Reduction: Efforts to minimize waste through closed-loop manufacturing and polymer recovery systems.

Spunbond Market Segmentation

By Material Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester (PET)

- Nylon (PA)

- Others (PLA, PU, etc.)

By Function:

- Disposable

- Durable

By Application:

- Personal Care & Hygiene

- Medical & Healthcare

- Agriculture

- Building & Construction

- Packaging

- Automotive

- Filtration

Regional Insights for Spunbond Market

Asia-Pacific:

Holds the largest Filtration and geotextile fabrics market share, led by China, India, and Japan, due to expanding hygiene product manufacturing, strong industrial base, and increasing consumer spending on healthcare and personal care.

North America:

Growth is driven by technological innovation, healthcare expansion, and sustainable product demand, particularly in the U.S. and Canada.

Europe:

Focuses on eco-friendly spunbond production and compliance with stringent environmental regulations. The region leads in biodegradable nonwoven development.

Latin America:

Experiencing increased demand for agricultural and hygiene applications, with Brazil and Mexico as key markets.

Middle East & Africa:

Emerging opportunities in construction, geotextiles, and healthcare, supported by infrastructure development and improving healthcare access.

Emerging Opportunities in Spunbond Market

- Rising Demand for Biodegradable Spunbond Fabrics: Supported by regulatory initiatives and eco-conscious consumers.

- Integration with Meltblown Technology (SMS Structures): Enhanced performance in filtration and medical protection.

- Expansion in Geotextile Applications: Infrastructure and environmental projects increasing demand.

- Growth of Nonwoven Packaging Solutions: Shift toward lightweight, recyclable, and sustainable packaging materials.

- Automation and Smart Manufacturing: AI-driven process control improving output efficiency.

Spunbond Market Future Outlook

The Spunbond Market Outlook is set for steady growth through 2032, driven by increased demand from hygiene, medical, and industrial sectors. The shift toward sustainable, biodegradable, and high-performance fabrics will define the next wave of innovation.

Manufacturers focusing on eco-friendly materials, automation, and smart production technologies are expected to gain a competitive edge in the evolving nonwoven industry landscape.

Spunbond Market Challenges

- Volatility in Polymer Prices: Dependence on petrochemical-based feedstocks affects cost stability.

- Environmental Concerns: Disposal of non-biodegradable spunbond materials remains a challenge.

- High Initial Setup Cost: Advanced machinery and energy-intensive processes require substantial capital investment.

- Competition from Woven and Knitted Alternatives: Certain applications still prefer traditional textiles.

For More Reports

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact :

Data Bridge Market Research Private Ltd .

3665 Kingsway — Suite 300 Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)